Burrs nikibazo gikunze kugaragara mugutunganya ibyuma, nko gucukura, guhindukira, gusya, no gukata ibyuma...

Kimwe mu byago bya burrs nuko byoroshye guca!Gukuraho burrs, ibikorwa bya kabiri byitwa deburring mubisanzwe birasabwa.3 gusibanganya no kurangiza ibice byuzuye birashobora kubara 30% yikiguzi cyigice cyarangiye.Na none, kurangiza icyiciro cya kabiri biragoye kuyikora, burrs rwose iba ikibazo cyoroshye.

Uburyo bwo gukemuraBURRS

1 Gukoresha intoki

Ubu ni uburyo gakondo kandi busanzwe bukoreshwa, ukoresheje amadosiye (dosiye yintoki na dosiye ya pneumatike), sandpaper, umukandara wumukandara, gusya imitwe, nibindi nkibikoresho bifasha.

Disadvantage: Igiciro cyakazi kirahenze, imikorere ntabwo iri hejuru cyane, kandi biragoye kuvanaho umwobo utoroshye.

Ibintu byakoreshwa: Ibisabwa bya tekiniki kubakozi ntabwo biri hejuru cyane, kandi birakwiriye kuri aluminium alloy bipfa guterwa hamwe na burr ntoya nuburyo bworoshye bwibicuruzwa.

2 Gupfa

Gutanga bikorwa bikorwa hakoreshejwe umusaruro upfa.

Ibibi: Bisaba umubare munini wurupfu (bikabije bipfa, gupfa neza) ikiguzi cyumusaruro, kandi birashobora no gukenera gukora shaping bipfa.

Ibintu bikoreshwa: Birakwiriye kuri aluminium alloy bipfa gupfa hamwe nibice byoroshye byo gutandukana, kandi imikorere ningaruka nziza nibyiza kuruta imirimo yintoki.

3 Gusya no gusiba

Ubu bwoko bwa deburring burimo kunyeganyega, kumusenyi, kuzunguruka, nibindi, kandi ubu bikoreshwa nibihingwa bipfa.

Ibibi: Hari ikibazo cyuko kuvanwaho bidafite isuku cyane, kandi nyuma yo gutunganya intoki za burr zisigaye cyangwa ubundi buryo bwo gusiba.

Ibikoresho bikoreshwa: bikwiranye na aluminiyumu ntoya yipfa gupfa hamwe nibice binini.

4 Gukonjesha

Koresha gukonjesha kugirango ushire vuba burrs, hanyuma utere ibisasu kugirango ukureho burr.Igiciro cyibikoresho ni 200.000 cyangwa 300.000;

Ibintu bikoreshwa: Bikwiranye na aluminium alloy bipfa gupfunyika hamwe na burr ntoya yubunini nubunini buto.

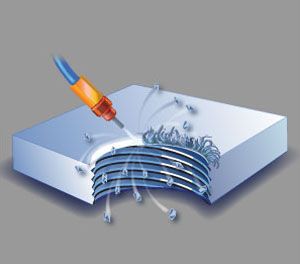

5 Guturika gushushe

Byitwa kandi gusohora amashyuza, guturika guturika.Mu kwinjiza gaze yaka umuriro mu itanura ryibikoresho, hanyuma binyuze mubikorwa byibitangazamakuru bimwe na bimwe, gaze ihita iturika, kandi ingufu zatewe nigisasu zikoreshwa mugushonga no gukuraho burr.

Ibibi: ibikoresho bihenze (miriyoni y'amadorari), ibisabwa bya tekinike yo gukora, gukora neza, ingaruka mbi (ingese, deformasiyo);

Ibikoresho bikoreshwa: Ahanini bikoreshwa mubice bimwe-byuzuye-ibice, nkibinyabiziga nibice byindege.

6 Gutanga imashini ishushanya

Igiciro cyibikoresho ntabwo gihenze cyane (ibihumbi icumi).

Ibintu bikoreshwa: Birakwiriye muburyo bworoshye bwimiterere nuburyo bworoshye kandi busanzwe bwo gutambuka.

7 Gutanga imiti

Ukoresheje ihame rya reaction ya electrochemical reaction, ibice bikozwe mubikoresho byicyuma birashobora guhita kandi bigahitamo.

Ibintu bikoreshwa: bikwiranye na burr imbere bigoye kuyikuramo, ikwiranye na burr nto (umubyimba uri munsi yinsinga 7) yibicuruzwa nkimibiri ya pompe numubiri wa valve.

8 Amashanyarazi

Uburyo bwa electrolytike yo gutunganya uburyo bwo gukuraho aluminium alloy ipfa-guta burrs na electrolysis.Electrolytic deburring irakwiriye gukuraho burr mubice byihishe bya aluminium alloy bipfa gupfuka, umwobo wambukiranya cyangwa ibice bifite imiterere igoye.Umusaruro uringaniye ni mwinshi, kandi igihe cyo gutangira ni amasegonda make kugeza kumasegonda mirongo.

Ibibi: Electrolyte irashobora kwangirika kurwego runaka, kandi hafi ya burr yibice nayo ikorerwa electrolysis, ubuso buzatakaza ubwiza bwumwimerere, ndetse bikagira ingaruka kumyizerere.Aluminium alloy ipfa-guta igomba guhanagurwa kandi ikagira ingese nyuma yo gutangira.

Ibintu bikoreshwa: Birakwiriye gusibanganya ibikoresho, guhuza inkoni, imibiri ya valve hamwe nu mwobo wamavuta ya crankshaft, hamwe no kuzenguruka inguni zikarishye.

9 Umuvuduko ukabije wamazi yindege

Gukoresha amazi nkigikoresho, irashobora gukoresha imbaraga zayo ako kanya kugirango ikureho burr na flash byakozwe nyuma yo gutunganywa, kandi mugihe kimwe, irashobora kugera kuntego yo gukora isuku.

Ibibi: Ibikoresho bihenze

Ibikoresho bikoreshwa: bikoreshwa cyane mumutima wimodoka hamwe na hydraulic sisitemu yo kugenzura imashini zubaka.

10 Ultrasonic deburring

Gusya kwa vibrasiya bisanzwe biragoye guhangana na burrs nk'imyobo.Ubusanzwe uburyo bwo gutunganya ibintu bitemba (inzira-ebyiri zitemba) busunika abrasive binyuze mumirongo ibiri ihagaritse itandukanijwe na silinderi kugirango itume isubira inyuma mumurongo wakozwe nakazi kakozwe.Kwinjira no gutembera kwangiza no kunyura ahantu hose hagabanijwe bizatanga ingaruka mbi.Umuvuduko wo gukuramo ugenzurwa kuri 7-200bar (100-3000 psi), ukwiranye nubwonko butandukanye nibihe bitandukanye.

Ibintu bishobora gukoreshwa: Irashobora gukora 0.35mm ya microporus burrs, nta burr ya kabiri yabyaye, kandi ibiranga amazi birashobora gukemura ibibazo bigoye.

11 Abrasive flow deburring

Gusya kwa vibrasiya bisanzwe biragoye guhangana na burrs nk'imyobo.Ubusanzwe uburyo bwo gutunganya ibintu bitemba (inzira-ebyiri zitemba) busunika abrasive binyuze mumirongo ibiri ihagaritse itandukanijwe na silinderi kugirango itume isubira inyuma mumurongo wakozwe nakazi kakozwe.Kwinjira no gutembera kwangiza no kunyura ahantu hose hagabanijwe bizatanga ingaruka mbi.Umuvuduko wo gukuramo ugenzurwa kuri 7-200bar (100-3000 psi), ukwiranye nubwonko butandukanye nibihe bitandukanye.

Ibintu bishobora gukoreshwa: Irashobora gukora 0.35mm ya microporus burrs, nta burr ya kabiri yabyaye, kandi ibiranga amazi birashobora gukemura ibibazo bigoye.

12 Magnetic deburring

Gusya kwa Magnetique ni uko mugikorwa cyumurima ukomeye wa magnetiki, abrasitike ya magnetiki yuzuyemo umurima wa magneti itondekanya icyerekezo cyumurongo wumurongo wa magneti, ugashyirwa kumurongo wa rukuruzi kugirango ukore "brushes abrasive", kandi bikabyara igitutu runaka kuri ubuso bwakazi, hamwe na magnetiki pole itwara "abrasives".Mugihe brush irizunguruka, igumana icyuho runaka kandi ikagenda hejuru yumurimo wakazi, kugirango tumenye kurangiza ubuso bwakazi.

Ibiranga: igiciro gito, intera yagutse, imikorere yoroshye

Ibintu bitunganijwe: gusya, imbaraga za magnetiki imbaraga, umuvuduko wakazi, nibindi.

Igice cyo gusya

Ihame risa no gukuramo intoki, usibye ko imbaraga zahinduwe robot.Hatewe inkunga na tekinoroji ya progaramu na tekinoroji yo kugenzura imbaraga, gusya byoroshye (guhindura umuvuduko n'umuvuduko) biragaragara, kandi ibyiza byo gukuramo robot biragaragara.

Ugereranije n'abantu, robot zifite ibiranga: kunoza imikorere, kuzamura ireme, nigiciro kinini

Burrs mubibazo bidasanzwe byasya ibice

Mu bice byasya, gusibanganya biragoye kandi bihenze cyane, kuko burr nyinshi zakozwe ahantu hatandukanye mubunini butandukanye.Aha niho uhitamo inzira iboneye kugirango ugabanye burr ingano iba ikomeye cyane.

Igihe cyo kohereza: Nzeri-29-2022